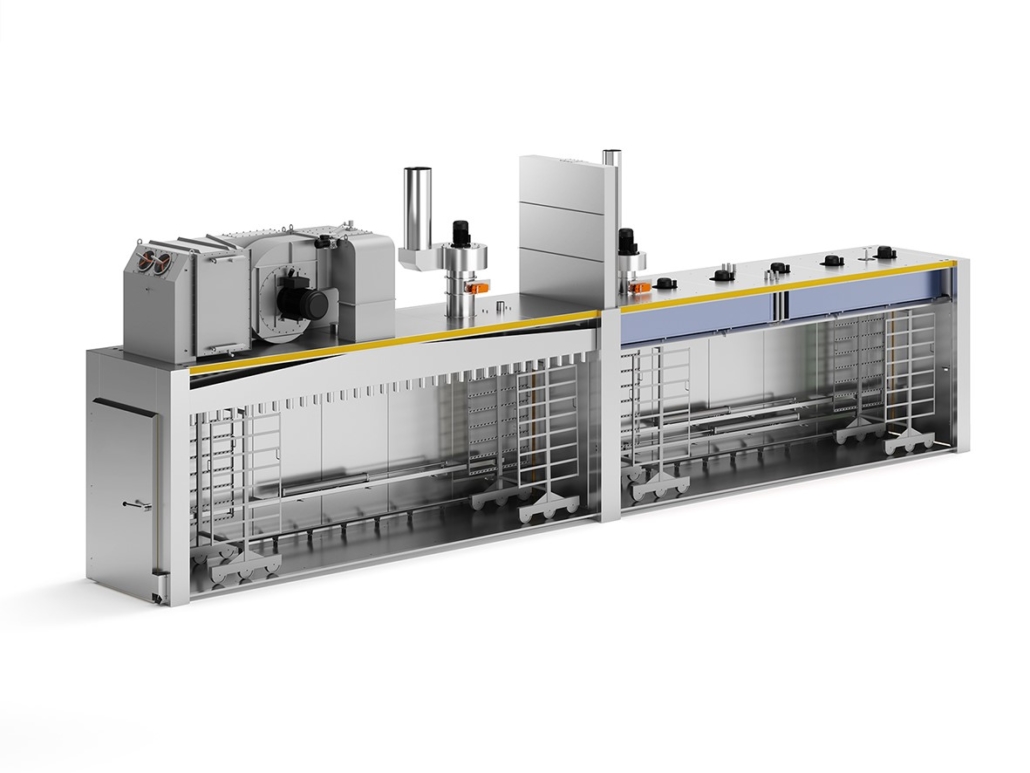

SEMI CONTINUOUS SMOKING/COOLING

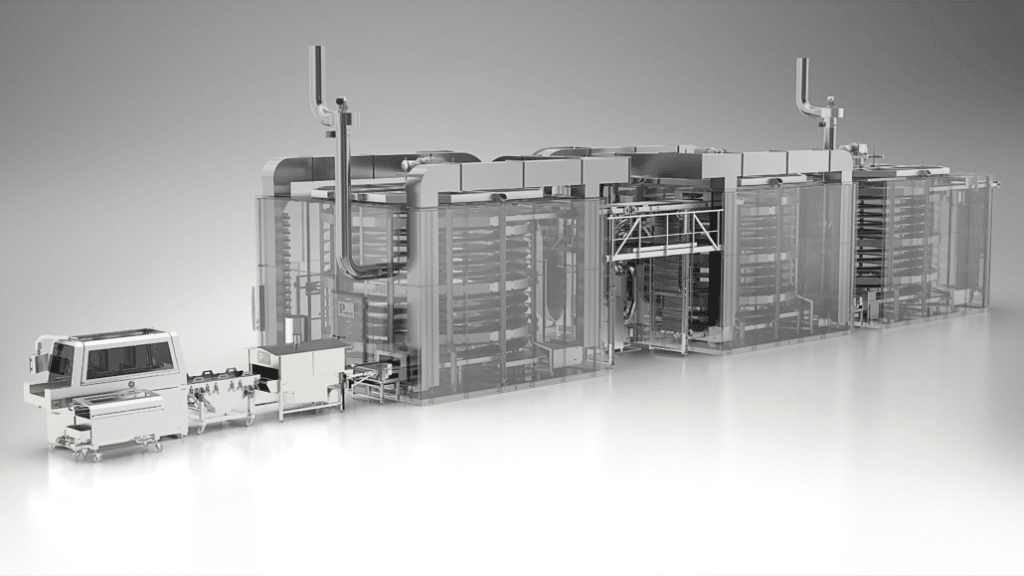

The smoke chamber with intensive cooling is constructed for drying, smoking, boiling and cooling sausage, bacon and similar products. The cooling takes place in a separate section of the cabinet. Between the two sections, trolleys are being transported automatically. The equipment consists of an all welded chamber with forced air circulation guaranteeing an evenly heated and smoked product.

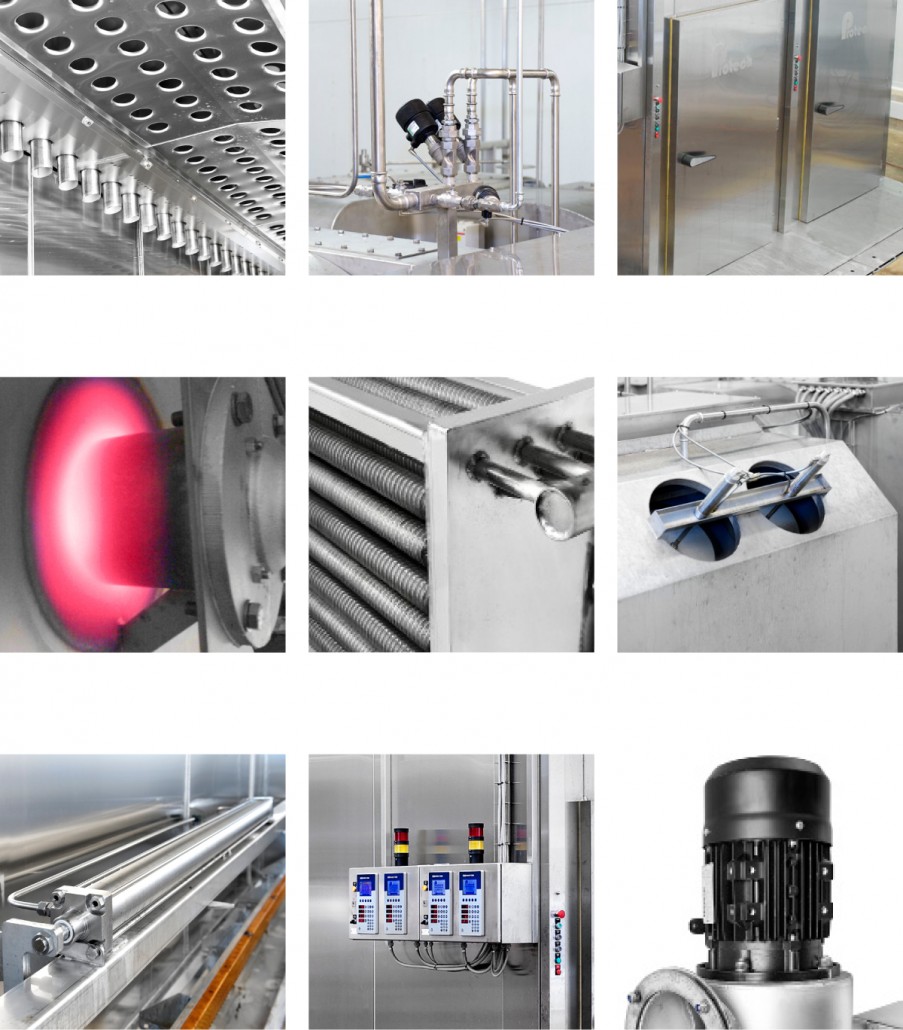

PERFECT AIR CIRCULATION

The unique alternating flap system continuously changes the air circulation across all the products. This ensures a completely even and dry smoke process for all the products and ensures an even color and weight reduction throughout the entire chamber. The forced air circulation is produced by a heavy duty centrifugal fan which is controlled by a frequency converter for exact air flow. This allows for a very exact and correct air speed for each individual product.

ALL IN ONE CONSTRUCTION

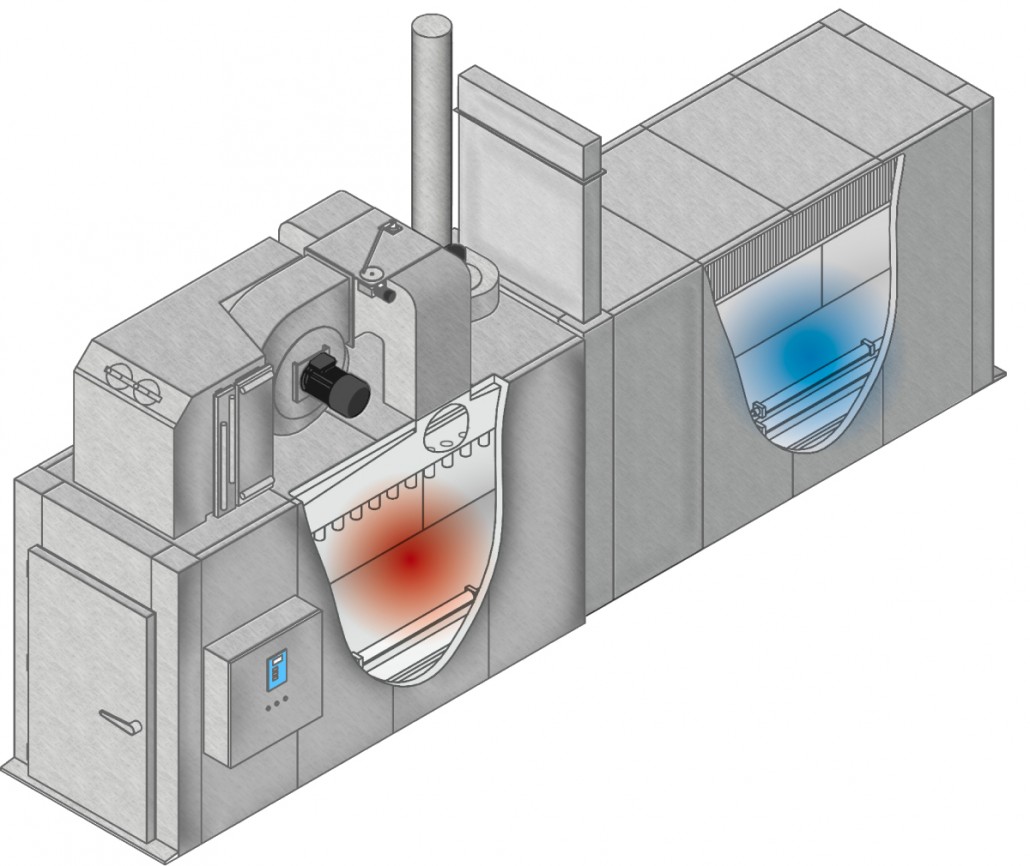

The entire smoker and cooler connected together – ensures a smooth transaction between the smoke chamber and the cooling chamber. The smokehouse itself (as seen below) is where the product gets heat treated, smoked and the products gets their flavours.

INTENSIVE COOLING CHAMBER

Constructed to cool down the product after smoking and cooking before it is transported to packing or refrigeration. The cooling process can be done using water and air or brine.

AUTOMATIC TRANSPORTATION

The complete unit comes with an automatic transportation setup that takes the products from the smoke chamber to the cooling chamber when each process is completed, ensuring a 100% time efficiency for the entire production.

Tap for larger image.

The cooling section can utilize air, water, or brine depending on product requirements. This rapid cooling stage ensures the product is properly conditioned before packing or cold storage.

The system uses a unique alternating flap mechanism that constantly adjusts airflow across the chamber. Combined with a frequency-controlled fan, this ensures uniform color, weight reduction, and smoke distribution for all products.

A semi-continuous smoking/cooling system is an automated solution for drying, smoking, cooking, and cooling products like sausages and bacon. The entire process happens in connected chambers, allowing seamless trolley transport without manual handling.