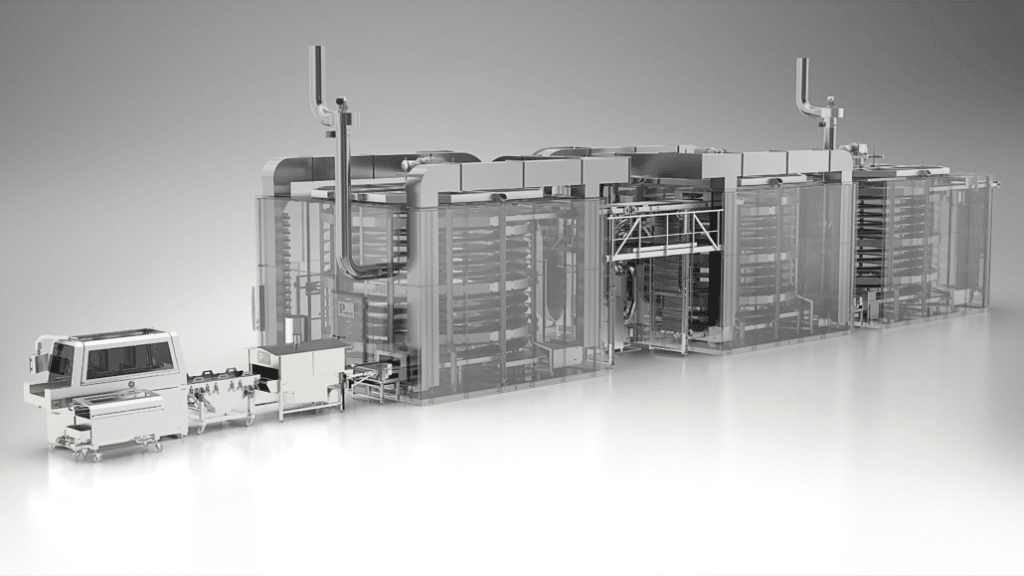

BATCH SMOKE CHAMBER

MEAT, FISH OR POULTRY

The smoke chamber is suited for drying, smoking and cooking processed meat products, fish and poultry within a temperature ranging between 15-90°C. The construction allows for processing of many different types of products in a cost efficient way with optimal results. The unique air circulation guarantees a consistent result for all products.

PERFECT AIR CIRCULATION

The unique alternating flap system continuously changes the air circulation across all the products. This ensures a completely even and dry smoke process for all the products and ensures an even color and weight reduction throughout the entire chamber. The forced air circulation is produced by a heavy duty centrifugal fan which is controlled by a frequency converter for exact air flow. This allows for a very exact and correct air speed for each individual product.

FLEXIBILITY AND QUALITY

As we both build and construct the machinery we can adjust the equipment according to our customers needs. Both construction and design can be tailored to suit their products and production. Components of the highest quality and use of the latest technology guarantees the equipment´s reliability and durability. All manufacturing and construction take place in a modern environment designed for food industry equipment.

Tap for larger image.

Yes. Since Protech designs and builds the machines in-house, both construction and design can be customized to fit your specific products and production requirements.

A heavy-duty centrifugal fan generates forced air circulation, which is precisely controlled by a frequency converter. This allows exact air speed tailored to each specific product.

The smoke chamber is designed for drying, smoking, and cooking processed meat, fish, and poultry at temperatures between 15–90 °C. It handles a wide range of product types in a cost-efficient and reliable way.