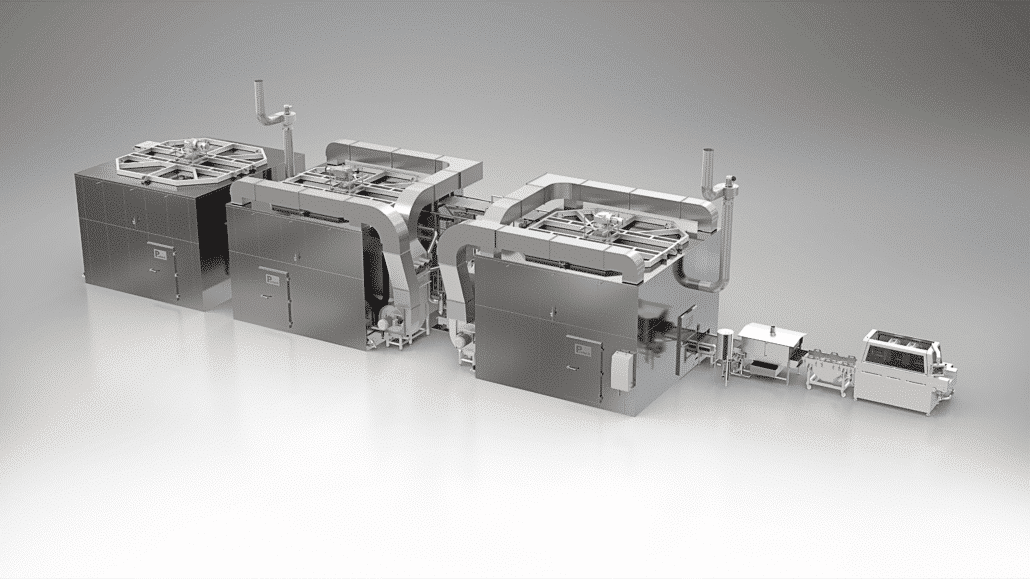

Spiral smoking is a method of smoking meat and fish that involves using a spiral smoking machine to impart flavor and preserve the food. The process involves hanging the meat or fish on racks inside the smoking chamber, where they are exposed to a continuous flow of smoke. This method is known for its ability to evenly distribute smoke throughout the food, resulting in a consistent and flavorful end product. Spiral smoking machines are designed to automate the smoking process, making it more efficient and consistent than traditional smoking methods. This technology has revolutionized the way meat and fish are smoked, allowing for greater control over the smoking process and producing high-quality, flavorful products.

Spiral smoking machines are equipped with advanced technology that allows for precise control over the smoking process. The machines are designed to regulate temperature, humidity, and smoke levels, ensuring that the food is smoked to perfection. This level of control is essential for producing high-quality smoked products, as it allows for consistency and repeatability in the smoking process. Spiral smoking machines are also designed to be user-friendly, making them accessible to a wide range of food producers. With their ability to automate the smoking process, these machines have become an essential tool for food processing facilities looking to produce high-quality smoked products efficiently and consistently.

The Benefits of Spiral Smoking Machines for Meat and Fish

Spiral smoking machines offer a range of benefits for meat and fish producers. One of the key advantages of using a spiral smoking machine is the ability to produce high-quality smoked products consistently. The machines are designed to regulate temperature, humidity, and smoke levels, ensuring that the food is smoked to perfection every time. This level of control is essential for producing consistent and repeatable results, which is crucial for meeting the demands of consumers and retailers. Additionally, spiral smoking machines are designed to be efficient, allowing for large quantities of meat and fish to be smoked at once. This makes them an ideal choice for food processing facilities looking to produce smoked products on a large scale.

Another benefit of using a spiral smoking machine is the ability to enhance the flavor and texture of meat and fish. The continuous flow of smoke in the smoking chamber allows for even distribution of flavor throughout the food, resulting in a rich and complex smoky flavor. This method of smoking also helps to preserve the food, extending its shelf life and ensuring that it remains fresh for longer. Additionally, spiral smoking machines are designed to be versatile, allowing for a wide range of meats and fish to be smoked. This makes them an ideal choice for food producers looking to diversify their product offerings and cater to a variety of consumer preferences.

How Spiral Smoking Enhances Flavor and Texture in Food Processing

Spiral smoking is known for its ability to enhance the flavor and texture of meat and fish. The continuous flow of smoke in the smoking chamber allows for even distribution of flavor throughout the food, resulting in a rich and complex smoky flavor. This method of smoking also helps to preserve the food, extending its shelf life and ensuring that it remains fresh for longer. Additionally, spiral smoking machines are designed to be versatile, allowing for a wide range of meats and fish to be smoked. This makes them an ideal choice for food producers looking to diversify their product offerings and cater to a variety of consumer preferences.

In addition to enhancing flavor, spiral smoking also helps to improve the texture of meat and fish. The slow smoking process allows for the proteins in the food to break down, resulting in a tender and juicy end product. This method of smoking also helps to seal in moisture, preventing the food from drying out during the smoking process. The result is a product that is not only flavorful but also succulent and tender, making it highly desirable to consumers. Spiral smoking machines are designed to optimize this process, ensuring that the food is smoked to perfection every time.

The Efficiency and Consistency of Spiral Smoking in Food Production

Spiral smoking machines offer a level of efficiency and consistency that is unmatched by traditional smoking methods. These machines are designed to regulate temperature, humidity, and smoke levels, ensuring that the food is smoked to perfection every time. This level of control is essential for producing consistent and repeatable results, which is crucial for meeting the demands of consumers and retailers. Additionally, spiral smoking machines are designed to be efficient, allowing for large quantities of meat and fish to be smoked at once. This makes them an ideal choice for food processing facilities looking to produce smoked products on a large scale.

The efficiency of spiral smoking machines also extends to their ability to automate the smoking process. These machines are equipped with advanced technology that allows for precise control over the smoking process, reducing the need for manual intervention. This not only saves time and labor costs but also ensures that the smoking process is carried out consistently every time. As a result, food producers can rely on spiral smoking machines to produce high-quality smoked products efficiently and consistently, meeting the demands of consumers and retailers.

The Versatility of Spiral Smoking for Different Types of Meat and Fish

Spiral smoking machines are designed to be versatile, allowing for a wide range of meats and fish to be smoked. This makes them an ideal choice for food producers looking to diversify their product offerings and cater to a variety of consumer preferences. Whether it’s beef, pork, chicken, or fish, spiral smoking machines can accommodate a variety of meats and fish, allowing producers to offer a diverse range of smoked products. This versatility is essential for meeting the demands of consumers who have diverse tastes and preferences when it comes to smoked products.

In addition to accommodating different types of meat and fish, spiral smoking machines also allow for a variety of flavors and seasonings to be used in the smoking process. This further enhances the versatility of these machines, allowing producers to create unique and innovative smoked products that cater to specific consumer preferences. Whether it’s hickory-smoked bacon or mesquite-smoked salmon, spiral smoking machines can accommodate a wide range of flavors and seasonings, making them an ideal choice for food producers looking to differentiate their products in the market.

The Importance of Quality Control in Spiral Smoking Processes

Quality control is essential in spiral smoking processes to ensure that high-quality smoked products are consistently produced. Spiral smoking machines are equipped with advanced technology that allows for precise control over the smoking process, ensuring that the food is smoked to perfection every time. This level of control is essential for producing consistent and repeatable results, which is crucial for meeting the demands of consumers and retailers. Additionally, quality control measures such as regular maintenance and calibration of spiral smoking machines are essential for ensuring that they continue to operate at peak performance.

In addition to machine maintenance, quality control in spiral smoking processes also involves monitoring the quality of the smoked products themselves. This includes regular testing of smoked products for flavor, texture, and shelf life, as well as adherence to food safety standards. By implementing rigorous quality control measures, food producers can ensure that their smoked products meet high standards of quality and safety, building trust with consumers and retailers alike.

The Future of Spiral Smoking Technology in the Food Industry

The future of spiral smoking technology in the food industry looks promising as more producers recognize its benefits in producing high-quality smoked products efficiently and consistently. As consumer demand for smoked products continues to grow, spiral smoking machines will play an increasingly important role in meeting these demands. With their ability to automate the smoking process and produce consistent results, these machines will become an essential tool for food processing facilities looking to produce high-quality smoked products on a large scale.

In addition to meeting current demands, spiral smoking technology also has the potential to drive innovation in the food industry by allowing producers to create unique and innovative smoked products that cater to specific consumer preferences. Whether it’s experimenting with different flavors and seasonings or developing new techniques for smoking meats and fish, spiral smoking technology will enable producers to differentiate their products in the market. As a result, we can expect to see a greater variety of high-quality smoked products on the market in the future, thanks to advancements in spiral smoking technology.

In conclusion, spiral smoking technology has revolutionized the way meat and fish are smoked, offering a range of benefits for producers looking to produce high-quality smoked products efficiently and consistently. With their ability to enhance flavor and texture, as well as their versatility in accommodating different types of meat and fish, spiral smoking machines have become an essential tool for food processing facilities. As consumer demand for smoked products continues to grow, we can expect spiral smoking technology to play an increasingly important role in meeting these demands while driving innovation in the food industry. With its potential for creating unique and innovative smoked products that cater to specific consumer preferences, spiral smoking technology has a bright future ahead in the food industry.