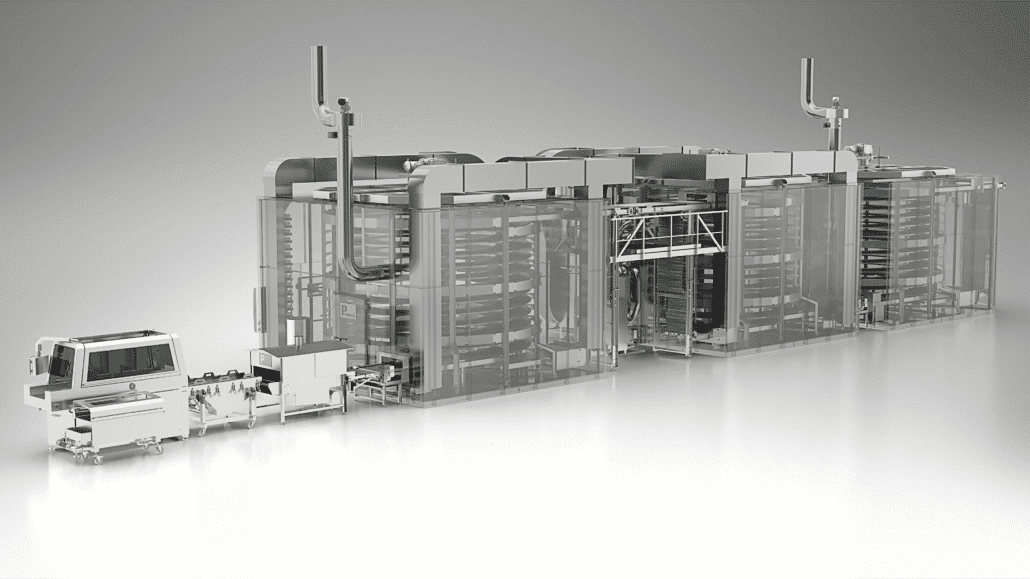

The Spiral Drying-Smoking-Cooking system is an advanced piece of equipment designed to enhance the efficiency and quality of bacon and similar meat products through continuous, in-line processing. This system integrates drying, smoking, and cooking functionalities within a single, streamlined unit, ensuring consistent results while optimizing production workflows.

Key Features

- Continuous Processing:

- The spiral design allows for uninterrupted, in-line processing, ensuring that products move seamlessly through the drying, smoking, and cooking phases without manual intervention. This continuous operation increases throughput and reduces handling times.

- Versatile Smoking Options:

- The system supports both traditional smoking and liquid smoke applications, providing flexibility in flavor development. Traditional smoking uses natural wood chips to impart a rich, authentic taste, while liquid smoke offers a more controlled and efficient method, suitable for varying production needs.

- Efficient Drying:

- The initial drying phase is crucial for preparing the bacon and similar products for smoking and cooking. The spiral design ensures even air distribution, allowing for uniform drying. This reduces the risk of spoilage and ensures consistent texture and quality across all products.

- Precision Cooking:

- The final cooking stage is meticulously controlled to achieve the desired internal temperature and texture. The spiral mechanism ensures even heat distribution, resulting in perfectly cooked products with minimal shrinkage and optimal flavor retention.

Smoke background

Benefits

- Enhanced Product Quality:

- The integrated approach ensures that each product receives uniform treatment, resulting in consistently high-quality outputs. The combination of traditional and liquid smoking methods allows for a diverse range of flavors, catering to various consumer preferences.

- Increased Efficiency:

- By combining drying, smoking, and cooking in a single unit, the system reduces the need for multiple pieces of equipment and streamlines the production process. This leads to significant time and labor savings, as well as lower operational costs.

- Space-Saving Design:

- The spiral configuration is compact, making it ideal for facilities with limited space. Despite its small footprint, the system handles high volumes, making it a valuable addition to any meat processing operation.

- Customizable Parameters:

- Operators can easily adjust temperature, humidity, smoke density, and cooking time to suit different product specifications. This flexibility allows for the production of a wide range of products with varying textures, flavors, and moisture levels.

Applications

While the Spiral Drying-Smoking-Cooking system is primarily designed for bacon, it is versatile enough to handle a variety of similar meat products. Sausages, hams, and other cured meats can also benefit from the uniform drying, rich smoking, and precise cooking that this system provides.

Conclusion

The Spiral Drying-Smoking-Cooking system represents a significant advancement in meat processing technology. By integrating three critical processing stages into a single, continuous operation, it enhances product quality, increases efficiency, and offers flexibility in flavor and texture customization. Whether using traditional smoking methods or liquid smoke, this system ensures that bacon and similar products are consistently produced to the highest standards.

See movie here: https://www.youtube.com/watch?v=14aENC6i23Y