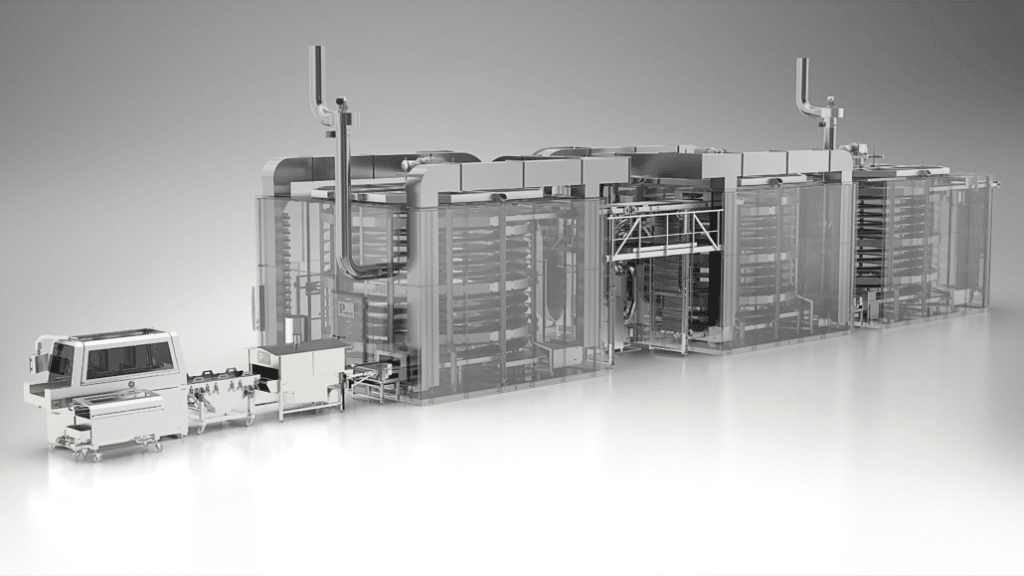

COLD SMOKING / FERMENTATION

The Cold Smoking and Maturing Plant is designed for smoking and maturing of salami, raw ham and similar meat products with a temperature of 15 – 35°C.

DESCRIPTION

The plant consists of a central air conditioning unit and tubes for existing room. A fan ensures uniform drying and treatment of the products. Smoke is supplied by a smoke generator placed together with the conditioning unit.

CONTROL

The plant is equipped with computer controls. The computer holds a capacity of 99 programmes, wich can be easily, found by the operator. Temperature and relative humidity are controlled precisely throughout process.

VENTILATION

The forced air-circulation in the room is produced by a powerful centrifugal fan placed outside the room. The fan is operated by a frequency control.

HEATING AND COOLING

Heating and cooling coil is made of stainless steel and placed together with the fan.

Tap for larger image.

Yes, Protech’s cold smoking and maturing system can be installed in an existing room or delivered as a complete cabinet, depending on the facility layout and production requirements.

The room is controlled by a microprocessor that automatically adjusts chamber temperature, core temperature, humidity, and duration. Up to 99 programmable settings can be stored for repeatable results.

A cold smoking room is used to smoke and mature meat products like salami and raw ham at temperatures between 12 and 35 °C. It provides the controlled climate needed for flavour development and shelf life.