Proper food cooling methods are essential in ensuring the safety and quality of food products. When food is not cooled properly, it can lead to the growth of harmful bacteria, which can cause foodborne illnesses. This is especially important in the food industry, where large quantities of food are produced and stored. Proper cooling methods help to slow down the growth of bacteria and prevent the risk of contamination. Additionally, proper cooling methods help to maintain the freshness and quality of food products, which is crucial for consumer satisfaction. By implementing effective cooling methods, food producers can ensure that their products meet safety standards and maintain their shelf life.

In large-scale food production operations, proper cooling methods are even more critical. With the high volume of food being produced, it is essential to have efficient cooling equipment that can handle the demand. Without proper cooling methods, food products can spoil quickly, leading to significant financial losses for the company. Furthermore, improper cooling can also lead to food safety issues, which can damage the reputation of the company and result in legal consequences. Therefore, investing in industrial cooling equipment is crucial for large-scale operations to ensure the safety and quality of their products.

Industrial Cooling Equipment for Large-Scale Operations

Industrial cooling equipment is designed to handle the high volume of food production in large-scale operations. These systems are specifically engineered to cool large quantities of food quickly and efficiently. One common type of industrial cooling equipment is blast chillers, which use high-velocity air to rapidly cool down hot food products. This method helps to minimize the time that food spends in the temperature danger zone, where bacteria can grow rapidly. Another type of industrial cooling equipment is plate chillers, which use a series of plates to cool down liquids or semi-liquids such as soups, sauces, or dairy products. These systems are designed to handle the high flow rates required in large-scale production facilities.

In addition to blast chillers and plate chillers, large-scale operations may also utilize tunnel freezers for freezing food products. These systems use a conveyor belt to move food products through a series of cold air or liquid nitrogen to rapidly freeze them. This method is particularly useful for preserving the quality of perishable food products such as fruits, vegetables, and seafood. Overall, industrial cooling equipment is essential for large-scale operations to ensure the safety and quality of their food products.

Efficiency and Benefits of Spiral Cooling Systems

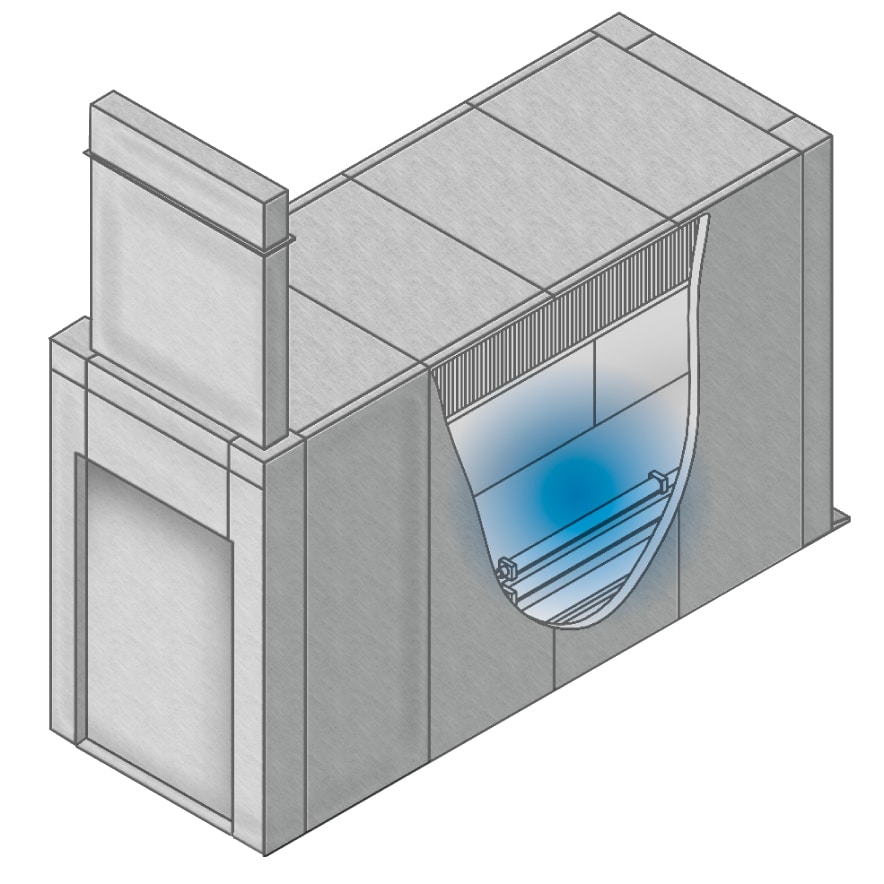

Spiral cooling systems are a popular choice for large-scale food production operations due to their efficiency and space-saving design. These systems use a spiral conveyor belt to move food products through a controlled cooling environment. The spiral design allows for a compact footprint, making it ideal for facilities with limited space. Additionally, spiral cooling systems offer a continuous cooling process, allowing for a high throughput of food products. This makes them an efficient choice for large-scale operations that require rapid cooling of their products.

One of the key benefits of spiral cooling systems is their ability to maintain the quality of food products during the cooling process. The controlled environment ensures that food products are cooled evenly and consistently, preventing any hot spots or uneven cooling. This helps to preserve the texture, flavor, and appearance of the food products, ensuring that they meet consumer expectations. Furthermore, spiral cooling systems are easy to clean and maintain, making them a cost-effective and practical choice for large-scale operations.

Batch Cooling Solutions for Small-Scale Production

While large-scale operations require industrial cooling equipment to handle high volumes of food production, small-scale producers can benefit from batch cooling solutions. Batch cooling systems are designed to cool smaller quantities of food products in a controlled environment. These systems are ideal for small-scale production facilities that produce artisanal or specialty food products. One common type of batch cooling system is a blast chiller, which uses rapid air circulation to cool down hot food products quickly. This method is particularly useful for small-scale producers who need to cool down small batches of freshly cooked or baked goods.

Another batch cooling solution for small-scale production is a cold room or walk-in cooler, which provides a controlled environment for storing and cooling food products. These systems are ideal for small-scale producers who need to store perishable items such as fruits, vegetables, or dairy products at the appropriate temperature. Cold rooms can also be used for chilling or freezing food products before packaging and distribution. Overall, batch cooling solutions are essential for small-scale producers to ensure the safety and quality of their food products.

Ensuring Food Safety through Effective Cooling

Effective cooling methods are crucial in ensuring the safety of food products throughout the production process. Proper cooling helps to slow down the growth of bacteria and prevent the risk of contamination, which can lead to foodborne illnesses. By implementing effective cooling methods, food producers can minimize the risk of microbial growth and ensure that their products meet safety standards. This is particularly important in the food industry, where consumer safety is paramount.

In addition to preventing bacterial growth, effective cooling also helps to maintain the freshness and quality of food products. Rapid cooling can help to preserve the texture, flavor, and appearance of food items, ensuring that they meet consumer expectations. Properly cooled food products also have a longer shelf life, reducing waste and maximizing profitability for producers. Overall, effective cooling methods play a critical role in ensuring the safety and quality of food products throughout the production process.

Innovations in Food Cooling Technology

In recent years, there have been significant innovations in food cooling technology that have revolutionized the way food products are cooled and preserved. One notable innovation is the development of smart cooling systems that utilize advanced sensors and automation technology to monitor and control the cooling process. These systems can adjust temperature and airflow settings in real-time to ensure that food products are cooled evenly and consistently. This level of precision helps to maintain the quality and safety of food products while minimizing energy consumption.

Another innovation in food cooling technology is the use of alternative refrigerants that are more environmentally friendly and energy-efficient. Traditional refrigerants such as hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) have been found to contribute to ozone depletion and global warming. As a result, there has been a push towards using natural refrigerants such as ammonia, carbon dioxide, or hydrocarbons in food cooling systems. These alternative refrigerants offer lower environmental impact and improved energy efficiency, making them a sustainable choice for food producers.

Choosing the Right Cooling Method for Your Food Production Needs

When it comes to choosing the right cooling method for your food production needs, it is essential to consider factors such as production volume, product type, space constraints, and budget. Large-scale operations with high production volumes may benefit from industrial cooling equipment such as blast chillers, plate chillers, or tunnel freezers. These systems are designed to handle the demand for rapid and efficient cooling of large quantities of food products.

On the other hand, small-scale producers may find batch cooling solutions such as blast chillers or cold rooms more suitable for their needs. These systems offer a cost-effective and practical way to cool smaller quantities of food products in a controlled environment. Additionally, advancements in technology have made smart cooling systems more accessible for producers of all sizes, offering precise control and energy efficiency.

In conclusion, proper food cooling methods are essential in ensuring the safety and quality of food products throughout the production process. Whether you are operating a large-scale production facility or a small-scale artisanal operation, choosing the right cooling method is crucial for maintaining consumer safety and satisfaction. By investing in efficient cooling equipment and staying abreast of innovations in food cooling technology, producers can ensure that their products meet safety standards while maximizing profitability.