In today’s competitive food industry, manufacturers face mounting pressure to increase productivity, reduce costs, and meet stringent quality standards. Protech’s innovative spiral technology offers a comprehensive solution to address these challenges, providing a highly efficient and versatile system for drying, smoking, and cooking a wide range of food products.

The Power of Spiral Technology

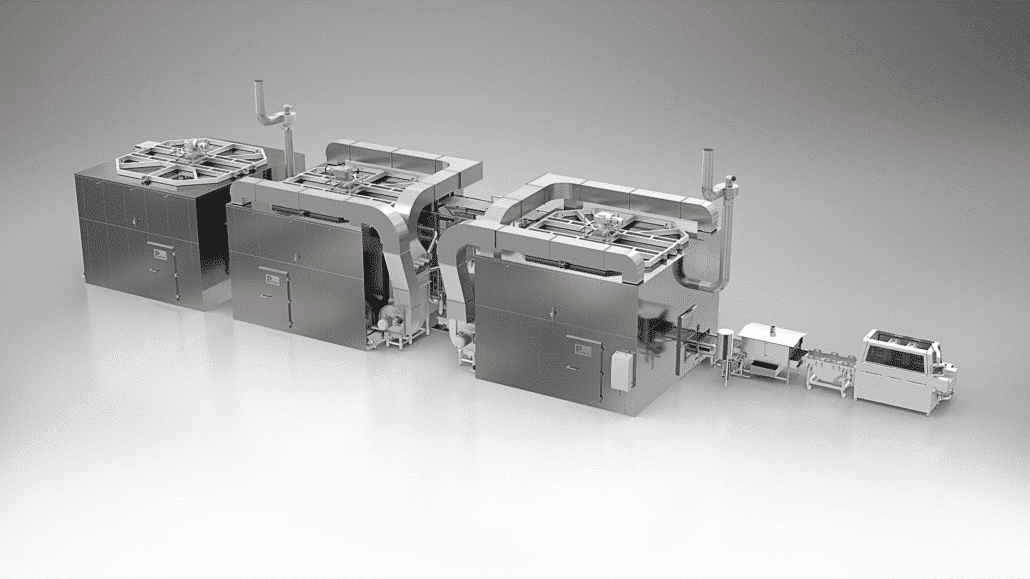

Protech’s spiral systems streamline food processing by combining multiple functions into a single, continuous process. This eliminates the need for separate equipment and handling, resulting in significant time and cost savings. The spiral design ensures uniform processing, with precise control over temperature, humidity, and airflow, leading to consistent product quality and reduced waste.

Benefits for Decision-Makers

- Increased Capacity: Protech’s spiral systems can significantly increase production capacity compared to traditional batch processing methods. This allows you to meet growing demand and expand your product offerings.

- Reduced Energy Consumption: The efficient design of the spiral systems minimizes energy usage, contributing to lower operating costs and a smaller environmental footprint.

- Improved Product Quality: Precise control over processing parameters ensures consistent product quality, reducing the risk of defects and maximizing yield.

- Shorter Lead Times: The continuous nature of the spiral process reduces production time, enabling you to respond quickly to market demands and improve delivery times.

Take the Next Step

Ready to discover how Protech’s spiral technology can transform your food production process? Have a look at our brochure below and read more about our complete product range.