Introduction

Sustainability in food production isn’t only about raw materials — it’s also about how factories manage hygiene, energy and water. Protech’s cleaning systems are designed to automate these processes, reducing waste and manual labour while maintaining top-level hygiene standards. The result is cleaner production with lower operating costs and environmental impact.

Cleaning Designed for Efficiency and Control

Protech has developed cleaning solutions tailored to modern food processing facilities. From centralised CIP systems to compact washers, each machine is built to provide powerful results with minimal resources. The use of stainless steel and precision-engineered nozzles ensures long service life and easy maintenance — essential for sustainable, continuous operation.

Protech Foam: Less Water, More Cleaning Power

Traditional cleaning methods rely on high water volumes. Protech Foam changes that. Its strong alkaline composition and foaming action allow for thorough cleaning with minimal water. The foam clings to surfaces longer, dissolving tar and soot effectively — ideal for smoke chambers and trolleys.

Benefits:

-

Reduces water consumption

-

Extends contact time for better cleaning

-

Minimises manual scrubbing and chemical waste

Automated CIP System: Clean-in-Place Sustainability

The Protech CIP System automates the cleaning of smoke and cooking chambers, controlled directly via each unit’s microprocessor. Automated dosing, central pumping, and recirculated water streams create an efficient closed loop. No manual labour is required — and water is reused, not wasted.

Advantages:

-

Fully automated, operator-free cleaning

-

Optimised detergent dosage

-

Water recirculation reduces resource use

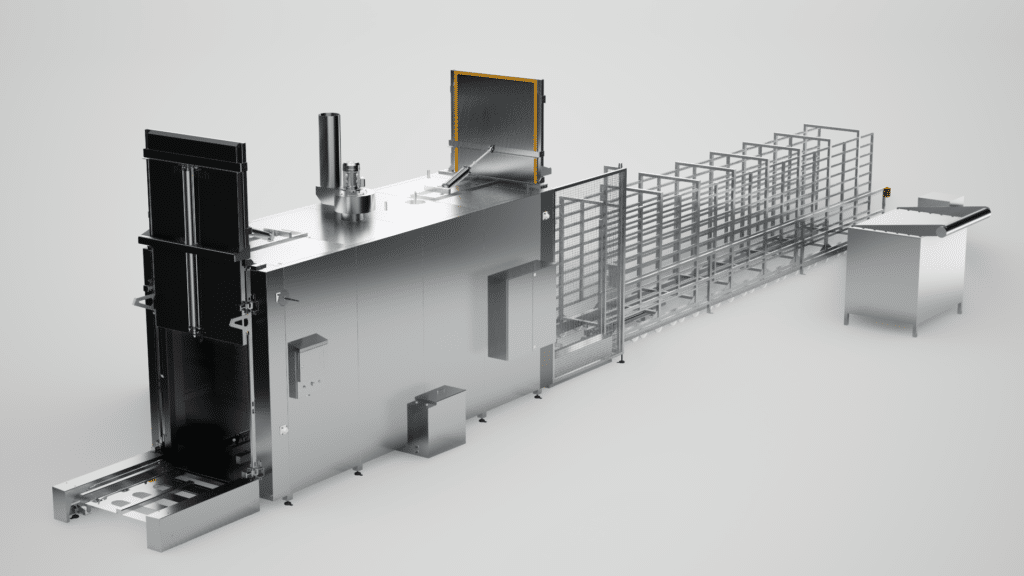

Compact Washers with Built-in Efficiency

Protech’s smoke stick and trolley washers are designed for high throughput in small spaces. The trolley washer cleans and pasteurises up to four carts in 15 minutes using steam and water recirculation. These systems eliminate the need for manual handling and contribute to a safer, cleaner workplace.

Conclusion: Automation That Supports Sustainable Food Processing

By combining advanced cleaning automation with reduced water and chemical use, Protech helps food producers achieve both hygiene and sustainability goals. The result: efficient operations, lower energy costs, and a smaller environmental footprint — without compromising product safety or quality.