Introduction

In industrial food production, cleaning is not just a regulatory requirement – it’s an essential part of quality assurance and operational efficiency. Protech has developed a full range of automated cleaning systems and a powerful foam detergent specifically designed for the challenges of cleaning smoke chambers, trolleys, tools and accessories. These solutions minimise downtime, reduce water consumption and eliminate manual labour — all while ensuring hygienic standards are met.

Protech Foam: Powerful Cleaning for Smoke Chambers

Protech Foam is a high-alkaline foam cleaning agent developed specifically for the food industry. It efficiently removes tar and soot — common residues in smoke chambers and trolleys — even after repeated smoking cycles. The foaming formula ensures the agent adheres to surfaces, improving contact time and cleaning performance.

Key Benefits:

-

Removes tar, soot and grease from smoke equipment

-

Strong alkaline formula for heavy-duty cleaning

-

Developed for modern food processing environments

Automated Cleaning with Protech CIP System

The Protech CIP (Cleaning-In-Place) system allows smoke and cooking chambers to be cleaned automatically, without supervision. Controlled via the chamber’s microprocessor, the system operates using a central pump, a buffer tank for water, and a dosing pump for detergent. Strategically placed nozzles ensure full coverage inside the chamber — no manual scrubbing required.

Ideal For:

-

Smoke chambers

-

Cooking chambers

-

Any facility requiring unattended, automated cleaning

Smoke Stick Washer for Tools and Hooks

The Protech Smoke Stick Washer is designed to clean slaughter hooks, smoke sticks, and other metal tools used in food production. The compact drum design ensures durable performance and reliable cleaning results.

Highlights:

-

Handles small tools and hanging accessories

-

Space-saving drum construction

-

Long service life and consistent wash quality

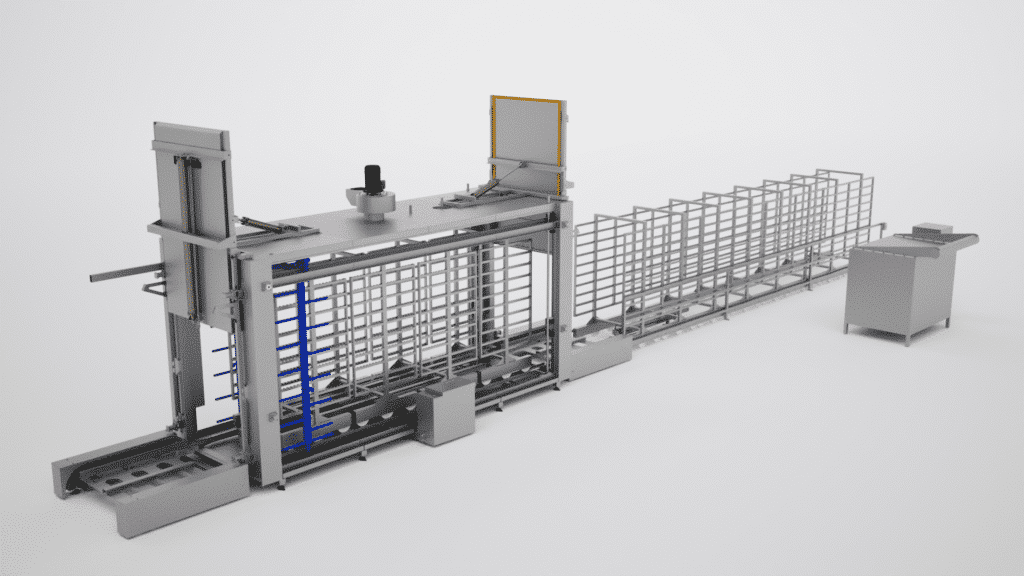

Trolley Washer: Fast, Automated Cart Washing

Protech’s automatic trolley washer handles both trolleys and nets — up to 4 units per cycle. Its built-in flushing system moves back and forth across the trolley to ensure thorough coverage. After washing, steam pasteurisation is applied for hygienic finish. An internal transport mechanism moves carts through the cabinet automatically, and the integrated water recirculation keeps water use to a minimum.

Performance:

-

Washes up to 4 trolleys + nets in 15 minutes

-

Steam pasteurisation included

-

No manual cart handling required

-

Low water consumption with recirculation

Conclusion: Efficient, Automated Cleaning for Food Producers

Protech’s cleaning systems and Protech Foam detergent deliver consistent, automated hygiene in food processing facilities. From smoke chamber cleaning to trolley and tool washing, these solutions support high productivity, water efficiency and food safety compliance — all without manual labour.

Learn More

Explore Protech’s Cleaning Systems:

https://protech-ab.se/en/product-range/

Contact us for tailored solutions:

https://protech-ab.se/en/contact/