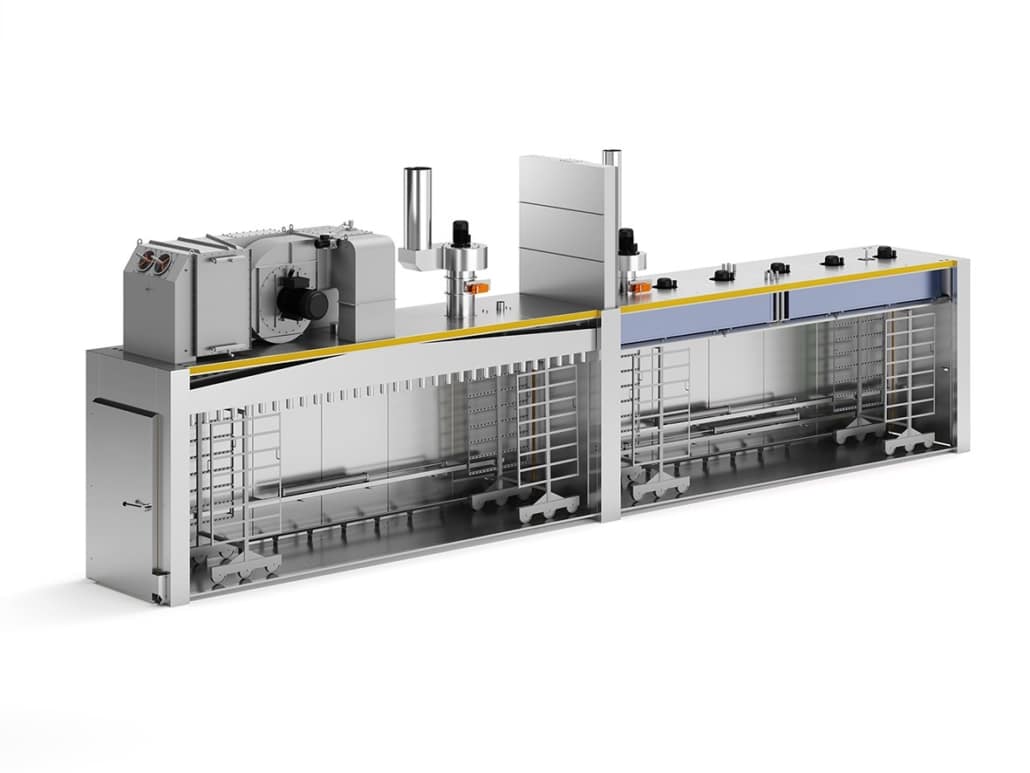

Modern food production demands agility and adaptability. Protech’s semi-continuous smoking and cooling systems empower manufacturers to respond effectively to changing market trends and customer preferences. These systems offer a unique combination of flexibility, precision, and efficiency, enabling you to optimize your processes for a wide variety of products.

The Advantages of Semi-Continuous Processing

Unlike traditional batch processing, semi-continuous systems allow for greater control over individual process parameters. This means you can fine-tune the smoking and cooling process to achieve the exact desired flavor, texture, and appearance for each product. This level of control minimizes waste, improves product quality, and enhances consistency.

Key Benefits

- Enhanced Flexibility: Easily adjust processing parameters to accommodate different product types and production volumes.

- Improved Product Quality: Precise control over temperature, humidity, and airflow ensures optimal product quality and consistency.

- Reduced Waste: Minimize product loss due to overcooking or inconsistent processing.

- Increased Efficiency: Optimize resource utilization and reduce downtime with continuous operation.

Unlock the Potential of Semi-Continuous Processing

Download PDF Product Sheet:

https://protech-ab.se/wp-content/uploads/2024/01/SEMICONTINIOUS.pdf